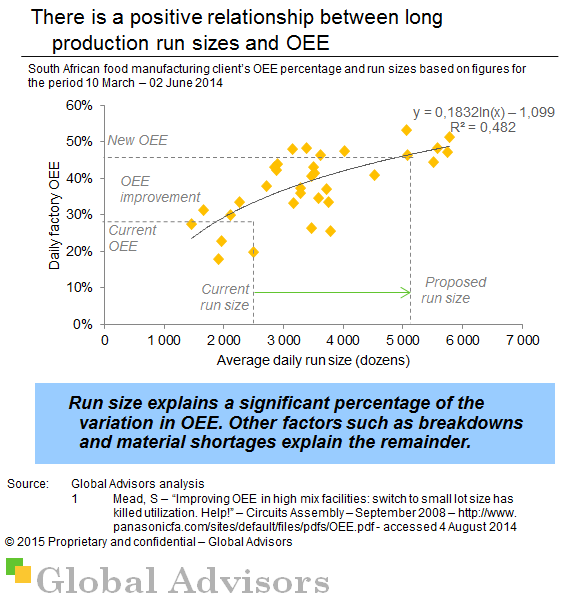

- Evidence suggests that longer run sizes lead to increased overall equipment effectiveness (OEE).

- OEE is a measure of how effectively manufacturing equipment is utilised and is defined as a product of machine availability, machine performance and product quality.

- Increasing run sizes improves availability as a result of less change over time, and performance as a result of less operator inefficiency.

- North America facilities that previously ran at world-class OEE rates, have experienced lower OEE rates due to a move towards reduced lot sizes and shifting large volume production overseas1.

- Shorter run sizes resulted in increased changeover frequency which led to increased planned downtime and reduced asset utilization.

- As a result OEE rates dropped from 85% to as low as 50%1.